- Keywords: Energy efficiency, Ceramic tiles and bricks, Porosity, Ventilated facade, Floor heating

In the last years, the sustainability has become the driving force for the development of new technologies aimed at improving buildings energy efficiency and building environmental quality. The development of new products for the construction field, able to enhance buildings energy efficiency and urban redevelopment, is one of the main needs in this sector.

Even if ceramic tiles are generally used because of their performances in terms of mechanical resistance, durability and aesthetical appearance, these can also be advantageously used for improve the energy efficiency of buildings.

For several years Centro Ceramico has been working to improve the thermal performances of traditional ceramic materials (tiles and bricks) with regard, in particular, to the design and the development of:

- coupled materials for ventilated facades

- systems to promote and facilitate the installation of floor heating

- tailored porous materials

with the aim to obtain versatile solutions able to qualify the ceramic tile product with regard to its end use.

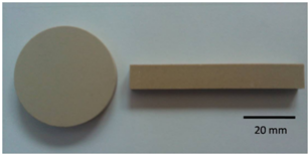

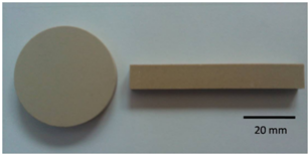

Internal studies on this topic have conducted to interesting results. Porcelain stoneware with tailored porosity has been designed and developed in form of a laboratory prototype (Figure 1). The as developed product showed:

- improved performances in terms of thermal insulation (thermal conductivity: <25-30% compared to conventional porcelain stoneware)

- an improvement in the reliability of mechanical properties (flexural strength: <15%; Weibull modulus >250% compared to conventional porcelain stoneware).

Main Scientific Papers

- E. Rambaldi, F. Prete, M.C. Bignozzi: “Acoustic and thermal performances of ceramic tiles and tiling systems”, Ceramics International, Review Article, Ceramics International, 41, 6, 7252-7260, 2015.

- E. Rambaldi, F. Prete, G. Timellini, “Thermal and acoustic performances of porcelain stoneware tiles”, Qualicer, XIIIth World congress on ceramic tile quality, Castellon de la Plana, Spain, 17-18 February 2014, Proceedings, 4pp, ISBN-13 978-84-95931-25-2, Cámara de Comercio de Castellón.

- E. Rambaldi, A. Lindeman: “Thermal performances of silicatic based materials”, cfi-Ber. DKG, 89(3), 2012, 29-33.

- E. Rambaldi, A. Salomoni, G. Timellini, A. Lindeman: “Thermal and mechanical performances of porous porcelain stoneware tiles”, XII International Conference & Exhibition of the European Ceramic Society, 19-23 June, 2011, Stockholm, Sweden.

- E. Rambaldi, L. Esposito, “Thermal performances of porcelain stoneware tiles containing polishing waste”, Ecomondo, 13a Fiera Internazionale del Recupero di Materia ed Energia e dello Sviluppo Sostenibile, Rimini, 28-31 Ottobre 2009, Atti dei seminari a cura di Luciano Morselli, 1086-1091, Maggioli Ed., ISBN 978-88-387-5360-1.

- V. Cannillo, L. Esposito, E. Rambaldi, A. Sola, A. Tucci: “ Investigation of the effect of porosity on porcelanized stoneware tiles by a multi-layered model”, Ceramics International, 35, 2009, 205-211.

- E. Rambaldi, A. Salomoni, G. Timellini, “Characteristics of ceramic tiles contributing to building energy efficiency”, Proceeding books of the 1st International Ceramic, Glass, Porcelain Enamel, Glaze and Pigment Congress, Seres’09, Eskisehir, Turkey, 12-14 October 2009, pp.169-176, ISBN 978-975-94814-7-6M.

- Gombia, P. Fantazzini, E. Rambaldi, A. Tucci, L. Esposito, G. Timellini: “Water 1H NMR technique to analyse the porous structure of ceramics”, Advanced Engineering Materials, 10 (3), 2008, 235-240.

- A. Sola, V. Cannillo, L. Esposito, E. Rambaldi, A. Tucci: “Modelling of porcellanized stoneware as a functionally graded material”, X International Conference & Exhibition of the European Ceramic Society, 17-21 June, 2007, Berlin, Germany.

- E. Rambaldi, A. Tucci, L. Esposito, G. Timellini, P. Fantazzini: “NMR techniques to analyse the porous structure of ceramics”, EUROMAT 2007, The biennial meeting of the Federation of the European Materials Societies (FEMS), 10-13 September, 2007, Nürnberg, Germany.

- L. Esposito, G. Pellicelli, E. Rambaldi, G. Timellini, A. Tucci: “A steel-ceramic matrix composite for an innovative porcelain stoneware product”, X International Conference & Exhibition of the European Ceramic Society, 17-21 June, 2007, Berlin, Germany.

Contacts:

|

Figure 1 Figure 1 |

|

|

Research Projects

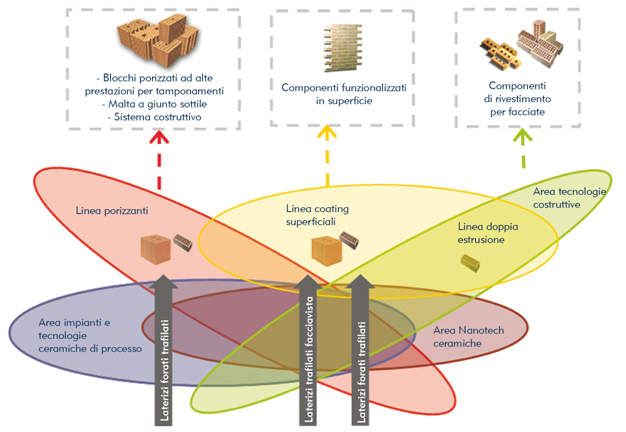

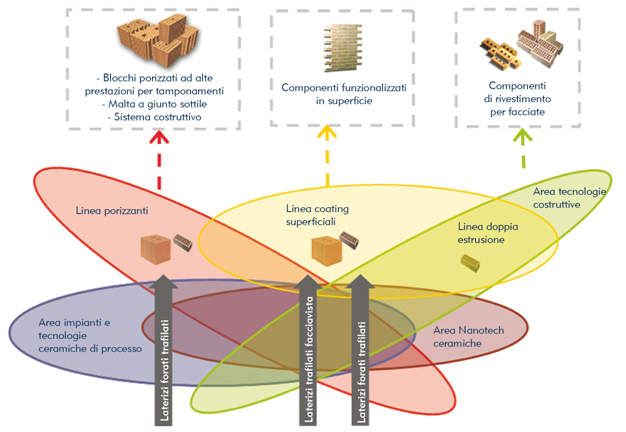

- Project ITALICI

Innovation and tradition for technological advance of the heavy clay industry and internationalisation of Italian building.

MSE – Industria 2015 – Made in Italy, 2009

- Project TECNOLATER

Expertise centre on heavy clay technology and building energy efficiency.

Emilia Romagna Region: Call “From production districts to technological districts”, 2010

![]()

![]()

![]()

Figure 1

Figure 1

![]()

![]()

![]()