Prototype device for the extrusion and drying behaviour control

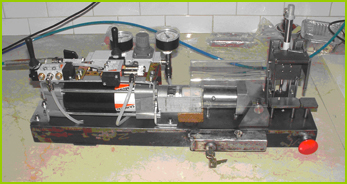

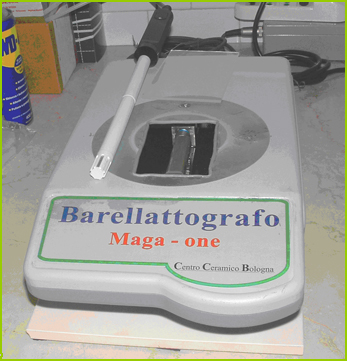

Centro Ceramico has achieved and developed a device that replaces the Adamel apparatus. The specimens to be tested are prepared and sized by a piston extruder and compressed air cutting machine. The extruder allows to obtain specimens 15 x 15 x 65 mm with stable and reproducible characteristics. On these samples, the instrument detects the weight loss (modified technical balance) and dimensional variations (laser), by a continuous data acquisition and processing system using specific software. The temperature and moisture data are detected simultaneously, over the time frame in which the test is carried out. Thanks to data processing, it is possible to obtain the Bigot curve, representing the amount of evaporated water as a function of the shrinkage during the drying phase, occurred at room temperature for 24-48 hours.

Services to industry

This device, consisting of extruder and computerized system for monitoring shrinkage and weight loss, allows to prepare and investigate the test samples, reproducing on a laboratory scale the forming and drying phases relating to the manufacturing cycle of heavy clay products. This test allows to forecast the drying behaviour and contributes to increase the information on shaped materials, both at plastic and cast states.

Moreover, the specimens obtained can be further investigated by physical-mechanical procedures, both at green and fired states.

Capabilities of the device:

- extruding specimens with small dimensions

- working with small amounts of raw materials (< 1 kg)

- extruding both single clays and mixes currently in use and/or investigate for new bodies (for example, introducing a secondary raw material from a different production chain) in short times, without hindering the manufacturing process

- replacing the previous Adamel apparatus by a device able to continuously and automatically detect and process the data

- working with specimens for plastic shaping

- working with soft paste specimens of bricks

- working with cast specimens for sanitaryware.

Contact person:

Dr. Giuliana Bonvicini – e-mail bonvicini@centroceramico.it

Mobile: +39 340 2227688