Defects of traditional ceramics: diagnosis and solution

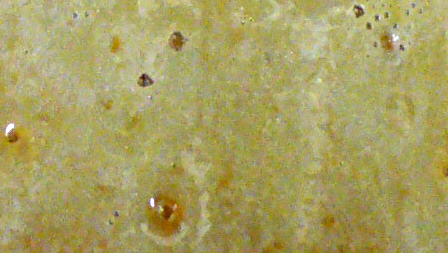

This package includes the study and analysis of defects, unevenness and effects visible on ceramic products at the end of the manufacturing cycle and/or after their use, such as “holes”, “cracks”, “dimples in the glaze”, “pinholes”, “black spots”, “side pitting”, “surface cracks”, “unglazed areas”, “black core”, stains, abrasions, detachment of material, corrosion, tarnishing, etc.

Here are the different steps included in the package:

1) Analysis of the defect – on the surface and/or cross-section – by:

- scanning electron microscopy (SEM) + energy dispersive microanalysis (EDS)

- optical microscopy (OM)

- optical profilometry, confocal or interferometric.

2) Correlations between the chemical and microstructural characteristics of the defect with the phases and/or with the different parameters of the manufacturing cycle:

- characteristics of the raw materials forming the body (chemical analysis by ICP-OES, and mineralogical analysis XRD) and analysis of the milling, spray-drying, pressing, drying phases

- characteristics of the raw materials of the glaze (chemical analysis by ICP-OES, and mineralogical analysis XRD) and analysis of the glazing and firing phases.

3) Correlation with the characteristics of the finished product using standardised test methods and not (Centro Ceramico internal methods) for the assessment, depending on the cases of:

- the aspect

- the physico-mechanical properties of the ceramic bulk

- the chemical-physical properties of the surface.

Contacts:

- Dr. Elisa Rambaldi: rambaldi@centroceramico.it

Direct phone number: +39 051 0250119

- Eng. Pietro Bruzzi: bruzzi@centroceramico.it

Direct phone number: Bologna +39 051 0250144

Sassuolo +39 0536 1700880

[/fusion_builder_row][/fusion_builder_container]